Features

1.00mm diameter enameled copper wire winding for ac dc motor

Specification

Make to order (MTO)

Bobbin Packages

Wooden spool, plastic spool, or according to customer requirements.

Details

Overview

Enameled Copper Wire is made of copper rod, which are draw by the specification mould,it is the baked winding wire with multiple-layers of insulating paint after annealing softening treatment.

Essential details

| Place of Origin: | Henan, China | Brand Name | LP Industry |

| Model Number: | enameled copper wire | Type | Insulated |

| Application: | transformer,motor,generator | Conductor Material: | Copper |

| Conductor Type: | Solid | Insulation Material: | Enameled |

| Color: | Natural | Diameter: | 0.016mm--7.0mm |

| Temperature class: | 130C~220C |

Supply Ability

Supply Ability: 1300 Ton/Tons per MonthPackaging & delivery

Packaging Details:Enameled aluminum wire packaging:

Standard Packaging: PT-25--PT-270

Inner packing: Different plastic spools according to wire sizes

Outer packing: Carton/wooden box or as customer required

Port:

Qingdao,Shanghai,Tianjin,Hongkong

Lead time:

| Quantity(kilograms) | 1 - 500 | >500 |

| Lead time (days) | 5 | To be negotiated |

Product Description

| Conductor | Copper | |||

| Dimension | 0.016-7.0mm | |||

| Thermal Class (℃) | 180 (Class H);200 (Class C);220 (Class C+); 240(Class HC) | |||

| Insulation thickness | G1;G2;G3;G4 | |||

| Standard | IEC,NEMA,GB,JIS | |||

| Certificate | UL | |||

| Packing | PT-4/PT-200 or Poly-wooden spool | |||

| Appication | Transformer;motor;generator;modern instrument;welding machine and so on | |||

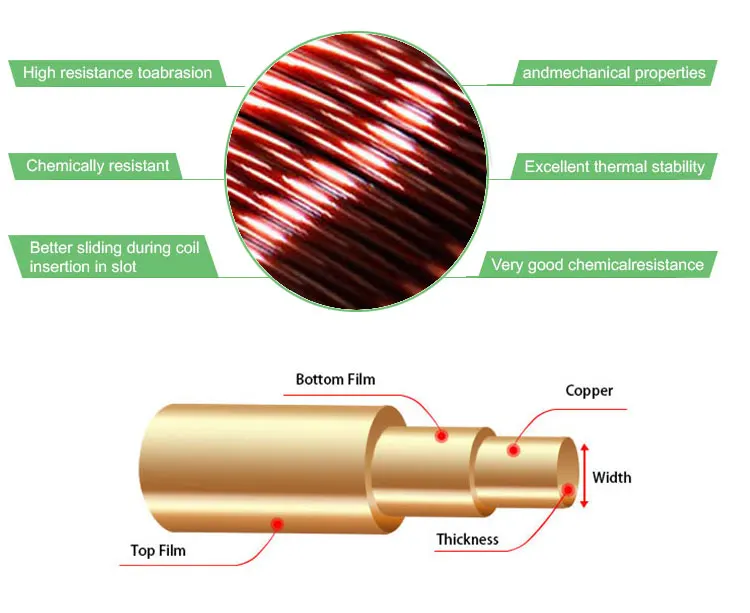

The insulation or overcoating used on enameled round wire is a type of polymer film (varnish) made from a variety of resins—typically polyester, polyglass, or polyamide—to create a tough, continuous layer of protection for the wire and allow for numerous windings in a coil without producing a short circuit.

Various types of varnishes produce different characteristics or properties, such as: High thermal index (AI) Abrasion resistance (NY) Self-bonding (SB) Self-lubricating (SL) Enameled round wire meets temperature classes between 105 °C and 240 °C, providing a guaranteed service life of 20,000 hours at the rated temperature. Magnet wire comes in a variety of sizes and shapes such as rectangular, square, and round. Enameled wire with a thermoplastic layer to bond the coils together is used to create self-supporting coils, which eliminate the need for a bobbin and accommodate tight spaces in various electronics applications.

The enameled copper wire is made of copper conductor and insulation materials, the insulation materials mainly include UEW, PEW and AIW, the temperature class 130℃, 155℃, 180℃, 200℃, 220℃ and 240℃. The color is natural and beautiful.

Types of enameled wire

1. Acetal enameled wire with two thermal grades of 105 and 120, used in the windings of oil-immersed transformers and oil-filled motors.

2. For polyester and modified polyester enameled wires, the thermal class of ordinary polyester enameled wire is 130, and the thermal class of enameled wire after modification is 155.

3. Polyurethane enameled wire; thermal grade is 130, 155, 180, 200. It is widely used in electronic appliances, precision instruments, telecommunications, and meters.

4. Polyesterimine/polyamide composite enameled wire, thermal class 180, widely used in windings of motors, electrical appliances, meters, power tools, and dry-type power transformers that require high heat resistance.

5. Polyesterimide/polyamideimide composite layer enameled wire is a heat-resistant enameled wire widely used at home and abroad. Its thermal class is 200. It is widely used in refrigerator compressors, air-conditioning compressors, electric tools, explosion-proof motors and motors and electrical appliances used under high temperature, high cold, radiation resistance, and overload conditions.

Company Profile

Certifications