Features

Double Layer Magnet Flat Aluminium Wire 3 Core 2.5mm Electrical

Specification

Make to order (MTO)

Bobbin Packages

Wooden spool, plastic spool, or according to customer requirements.

Details

Overview

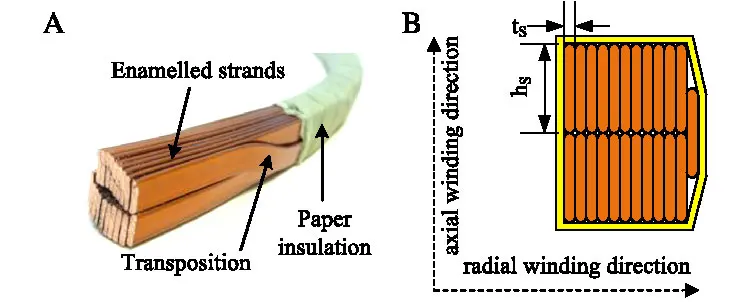

Continuously transposed cable (CTC) is a type of winding wires weaved by certain number of strips of enameled rectangular wires in two ranks according to special tectonics and wrapped by special insulation material. It is mainly used for large-scale oil-immersed power transformers, reactors and large-capacity dry type transformers.

Essential details

| Place of Origin: | Henan, China | Brand Name | LP CTC Cable |

| Model Number: | Flat aluminium wire | Type: | Insulated |

| Application: | Transformer, transmission line | Conductor Material: | Copper |

| Conductor Type: | Solid | Insulation Material: | Enamelled |

| Product name: | Continuously Transposed Conductor | Type enameled wire: | round or flat enameled wire |

| Insulation enamel: | Polyvinyl acetal enamel | Covered material: | paper or cotton wire |

| Temperature class: | 120 | Standard: | IEC,NEMA,GB,JIS |

| Usage: | Large transformer or transmission and distribution lines | Feature: | High strength, high temperature |

| suggested ratio of width and thickness: | 2.5<b/a<7.5 | Max width: | 26mm (excluding insulation) |

Supply Ability

Supply Ability: 250 Ton/Tons per MonthPackaging & delivery

Packaging Details:

Port:

Lead time:

| Quantity(kilograms) | 1 - 500 | >500 |

| Lead time (days) | 15 | To be negotiated |

Product Description

Polyvinyl acetal enameled with paper insulation CTC

CTC conductor can improve using rate of winding space, min-ish volume and reduce cost, most of all, it decline the loss of circumference and eddy loss caused by leaking of magnetic field and also has advantages of improving machine strength of winding and saving winding time.

| number of strips: | 7-49 | |||

| single dimension: | thickness of conductor a : 1.00-3.15mm width of conductor b : 3.00-12.50mm | |||

| suggested ratio of width and thickness: | 2.5 < b/a <7.5 | |||

| please connect us if your dimension is out of above range Insulation layers: | 24 | |||

| layers at one time. Max thickness of CTC: | 80mm (excluding insulation) | |||

| max width: | 26mm (excluding insulation) | |||

| Max.Height of CTC bundles: | 80mm (excluding paper insulation) | |||

| Max. Width of CTC bundles: | 26mm (excluding paper insulation) | |||

CTC Types

- Polyvinyl acetal enameled with paper insulation CTC

- Polyvinyl acetal enameled over coated bond able epoxy resin with paper insulation CTC

- Polyvinyl acetal enameled with paper insulation 、hardened copper CTC

- Polyvinyl acetal enameled over coated bond-able epoxy resin with paper insulation 、hard-ened copper CTC

- Polyester net covered CTC

- Polyestermide enameled with Nomex insula tion paper CTC

- Polyester fibre non-weaving modified polyes-ter enameled CTC

CTC Manufacturing Process

Two type manufacturing process:

1. 4-49 flat enameled copper or aluminum wire with paper covered

2. 4-49 flat enameled copper or aluminum wire with cotton wire